Conveyor Belt

Our Range of N 17 & M24 General Duty Conveyor Belts. N-17: These Conveyors Belts are mainly used For Conveying Bauxite, Asbestos, Ash, Chalk, Cement, Lime, Surface Coal etc. M24: These are mainly used in all mining industries and process industries such as Cement (limestone), Steel (crushed Metallic Ores), Stone Crushing Industries (Granite & blue Metal).

Chevron Conveyor Belt are Suitable for Conveying loose, Bulky or bagged materials on inclined surface at angles up to 40 degree. Cleats and top cover rubber are vulcanized integrally. Can be used on Conventional Carrying & return Idlers. Standard cleat height of 15MM.

For delivering optimum performance, this oil resistant belt constitutes of parts and components that come coated with machine oil as well as are heavy-oil treated to handle the movement needs of Coal in cooking plants & electric power generating plants, Soybean draft, Fish meat, other oily materials containing non-polar organic solvents and fuel.

With the belts designed to deliver high- temperature resistance to issues like tearing & abrasion, the solution delivered stands up to prolonged exposure, thus ensuring benefits like reduced maintenance & downtime, Lowered overall operating costs.

Food Grade Conveyor belting solutions delivered feature White Food Grade Conveyor as well as Elevator Belting that are precision manufactured as per IS:1891 (Part IV). Our Food Grade Belts are available in two distinct type of compositions, the first made from natural rubber suited for non-oil / acidic / reactive materials and the second is the Special synthetic rubber based.

These conveyor belts are apt to carry bulk solids, unit loads and even heavy materials. It is one of the most effective ways of elevating materials in a confined space, the economy is achieved by single belt operation, wide range material can be handled, less space and requirement, no transfer point, low maintenance and big capacity.

Shot-blasting is a method used to clean, strengthen (peen) or polish metal. Shot blasting is used in almost every industry that uses metal, including aerospace, automotive, construction, foundry, shipbuilding, rail, and many others.

Endless Conveyor Belts are produced through hot splice method in the manufacturing plant. Such belts are utilized in areas such as recycling sector, mobile crushing, screening and small conveyors. They ensure quick installation and low chance of failure at site.

Rough Top Conveyor belting solutions. offered comprise two as well as three ply construction choices that of NN/EP fabric which comes with surface texture that aids in resisting the tendency for material to roll back down the conveyor while at transportation stage. Typical Applications are For Lorry Loaders, belt flight Loaders, etc.

Excel Rubber Enterprise offers a wide range of white conveyor belt qualities for different industrial applications. Our in-house developed and thoroughly tested rubbers create an excellent base for reliable and safe transportation of sensitive materials which should not get contaminated nor colored by the belt.

We have the requisite expertise and experience to offer our clients superior range of imported conveyor belts such as PVC conveyor belts or Rough Top Conveyor. We have the facility of vulcanized joints, fused sidewalls, and cleats, tracking profiles to serve for elevating conveyors for food or other products. Made from premium grade of PVC material & fabric carcass, our PVC conveyor belts.

Conveyor Drum Pulley is a most common pulley used in conveyor system to support the conveyor belts, as it has the cylindrical shape like a drum, is renowned as a drum pulley. Conveyor Drum Pulley is highly developed by our shrewd team of professionals by utilizing high grade raw material like mild steel and electric resistance welding (ERW), which are source from the reliable vendors of the market.

We are manufacturers of complete range of Conveyor Roller having dia meter from 50 mm to 200 mm, roller length 1000 mm to 2000 mm. We manufacture roller with MS Steel.

The conveyor idler/roller is an important part of any conveyor system because they are used to effectively support the conveyor belt and bulk materials. Conveyor idlers/rollers consist of housing, shaft, bearing, housing, seals and snaps. These Conveyor Rollers are technologically advanced and confirm to industrial quality norms of international standard.

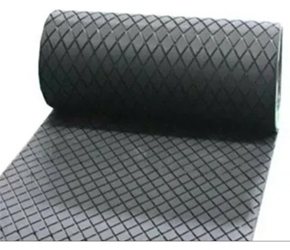

Diamond Rubber Sheet offered by us is basically designed to display outstanding abrasion and ozone resistance. This sheet prevents belt slippage and guards from wear and corrosion and decreases material build- up. Moreover, the finished products are tested on several parameters, in order to deliver a defect-less assortment to the clients.

Excel Rubber Enterprise is involved in Cold vulcanizing solution and hot vulcanizing solution. We have qualified engineers and technicians with vast experience in the field of Hot & Cold Vulcanizing of conveyor Belts at our works as well as customers site irrespective of distance and region. We also undertake annual contracts for Conveyor Belts Joining, Pulley - Legging.